The Art of Shoemaking

Opublikowano: 10 września 2015

In spite of the technological progress, it is stil believed that Goodyear welt construction, initiated in the 18th century, is the best production technique as far as men’s shoes are concerned (Loake shoes, for example, are produced in this way).

Four fundamental advantages of Goodyear welted footwear are as follows:

- The shoes can be reconstructed, which means that worn out parts (such as the sole or the cork) can be replaced and the upper of the shoe can be pulled over a last.

- No glue is used, so the shoes last longer.

- The cork adapts itself to the way of walking, which makes the shoes more comfortable.

- The shoes are mainly hand-made, so each pair is unique.

One pair can be in production for even up to 8 weeks (information provided by Loake). The entire process involves creating 75 footwear parts, which later undergo approx. 200 different operations performed by 130 craftsmen.

CUTTING / “CLICKING”

The process begins with leather parts of the upper being meticulously cut out. The name ”clicking” comes from the sound which the hand cutting knife makes as it is removed from the leather.

CLOSING

…is the moment when parts of the upper are sewn together. At this stage, it is time for operations such as “machining” (reducing in size) an excessively thick piece of leather, staining and folding the leather piece’s edge to improve its appearance.

LASTING

The upper is pulled over a selected last to be then attached to the insole, the heel and the sides of the shoe. Prior to that, the upper part of the shoe is left in a place where excessive humidity preventing the leather from getting into the right shape is removed.

WELT

A “welt” is a leather strip which is sewn together with the upper and the insole, and which will be later attached to the sole. Thanks to that, a skilled shoemaker can resole the shoe in future.

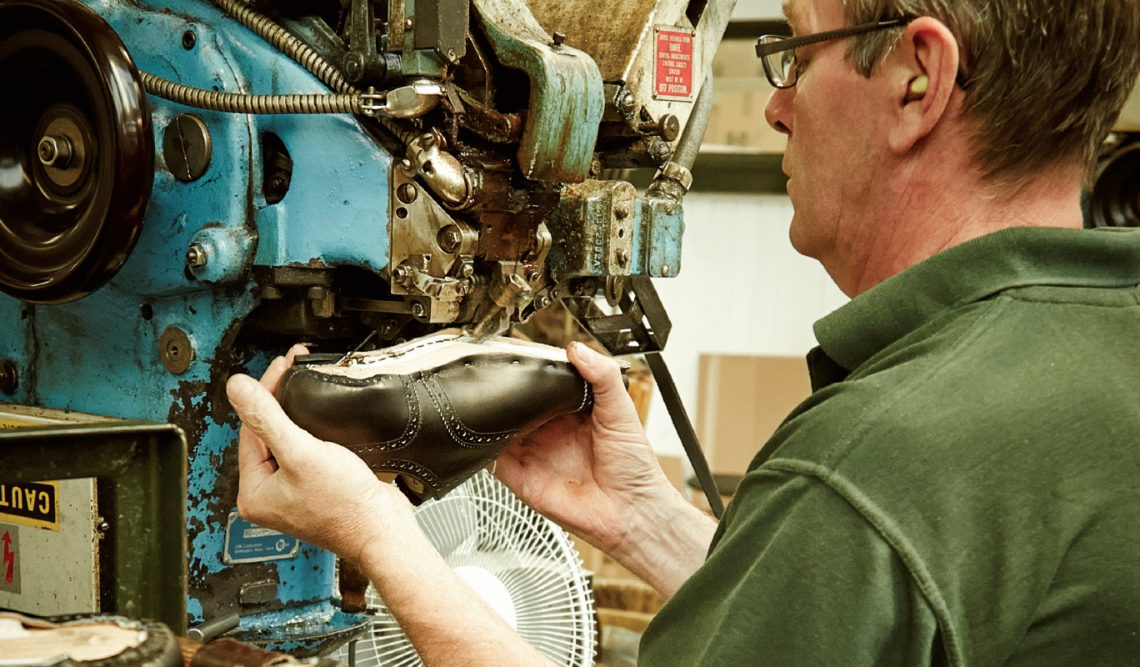

SOLE STITCHING

Stitching the sole to the welts guarantees durability.

EDGE TRIMMING

The edges of the sole are trimmed to a desired shape. It is a highly detailed work, and therefore is done “freehand”.

SOLE STAINING

BURNISHING / DRESSING

The last operations are burnishing, dressing and polishing shoes. This time-consuming activity is done entirely by hand. In further parts of the production process final details are being looked into, e.g. cutting out a so-called gentlemen’s notch.

Jarosław Blich

Tagi: art of shoemaking, craft, craftsmen, elegance, footwear, hand made, making the shoes, masterpiece, reconstruction of shoe, shoes

Dodaj komentarz